-

We unite our technical production capacity with the client’s needs to give from to the future.

-

We unite our technical production capacity with the client’s needs to give from to the future.

-

We unite our technical production capacity with the client’s needs to give from to the future.

-

We unite our technical production capacity with the client’s needs to give from to the future.

-

We unite our technical production capacity with the client’s needs to give from to the future.

Competence acquired in the sheet metal business over 50 years, allows Co.C.E.M. to meet all our clients’ demands and to guarantee their total satisfaction.

This is also made possible by the company’s flexibility in production, which uses advanced technologies and highly specialized personnel as well as carefully chosen raw materials, to obtain only the highest quality products, with fine finishes and maximum resistance. Able to also make customized products designed by clients, personalizing them according to the taste and specific demands of each client, the company places at their disposition all its experience to maximize client satisfaction and to always offer the best product for each need.

The cut;

Advanced technology for high productivity

The starting point for production of the object is the cutting phase; the use of two Laser cut units (Fiber e Co2) guarantees the readiness of the materials for the successive phases of processing in an organized and rapid manner.

The high productive flexibility of these machines as well as the possibility to work a great variety of materials and to make the most disparate shapes, permits the handing of this phase of processing in an adequate way.

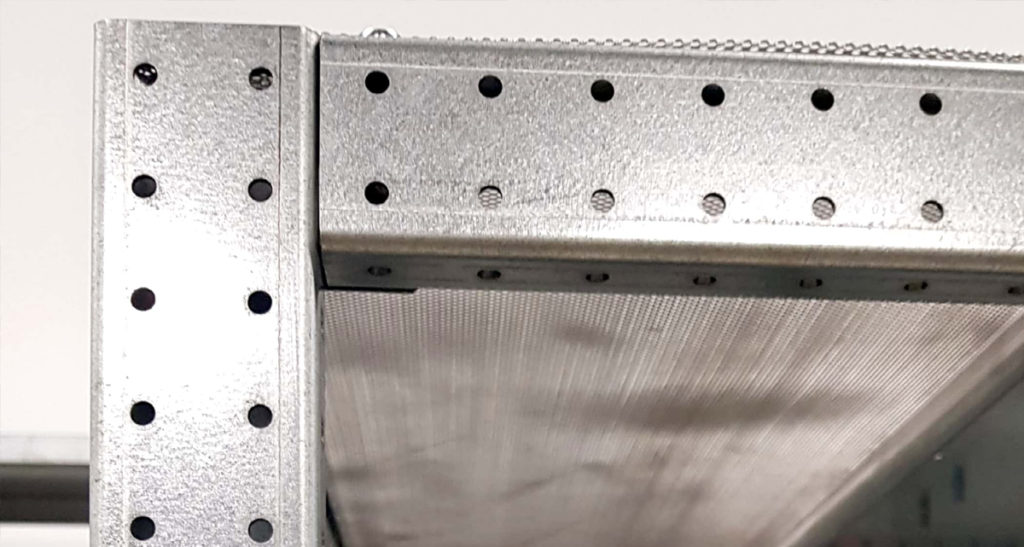

The punching;

Where the material is transformed

Modern machinery for punching can work sheets of metal with a maximum development of 3000mm x 1500mm of differing thickness. In this phase, besides the classic processes of drilling and cutting, we can do marking, personalized shaping and tapping.

The bending;

The product takes shape

The bending department has 5 numerically controlled bending machines. The characteristics of the bending machines, combined with the competence of the operators, allows us to obtain the highest precision in the manipulation of surfaces.

The trustworthiness and precision of our machines allow us to reach elevated quality standards and an excellent economic competitiveness both in the execution of prototypes and for larges series.

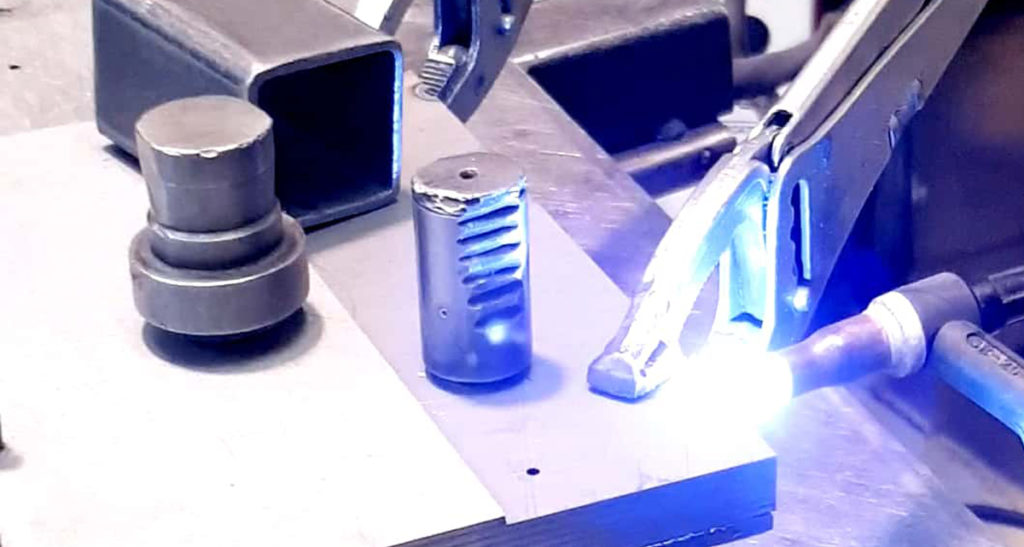

Welding;

Uniting aesthetic and functional

Of the fabrication phases, the welding of semi-finished products assumes a role of fundamental importance when the client necessitates a structure composed of numerous parts joined together permanently. Depending on the type of welding and raw materials used, the completed structure may have characteristics which are primarily aesthetic or else structural.

A careful attention to detail and an elevated level of finishes distinguish the final result in a definitive way.

The painting;

Aesthetics and protection

Paint in the form of electrostatic powder is a phase of fabrication that permits the covering of the metal surfaces with a colored layer.

This treatment, besides offering excellent results to the level of superficial finish, guarantees an important protection against the corrosive action of external agents.

![grande-basamento-2-1024×578[1]](https://www.cocem.it/wp-content/uploads/2019/06/grande-basamento-2-1024x5781.jpg)

Assembly;

A service with added value

The eventual assembly phase is always important for the market because it furnishes the client with the most complete product possible. The company has at its disposition specific departments for assemblage, o semi-assemblage of components and details often requested by specific market demands. Besides the added value, the client receives a completely personalized product which responds to their own technical specifications.